The medical device industry will gather in Düsseldorf from November 17–20, 2025 – and rose plastic medical packaging will be right at the heart of it.…

Read more

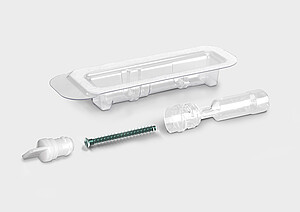

New: QuadroPack TPU

Intuitive handling and versatile use.

Protects sensitive products.

Precisely fitting, professional, ready for use.

Our medical device packaging meets the highest standards – just like your product

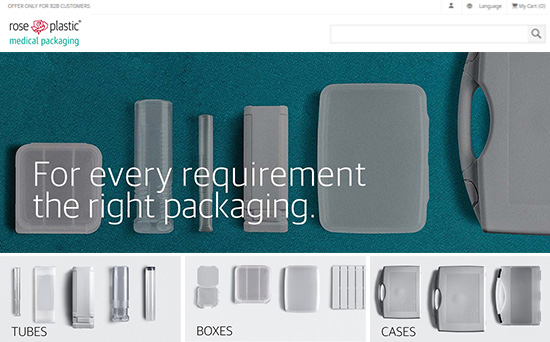

Challenging requirements do not deter us – they inspire us! To do what, exactly? To create intelligent packaging solutions for your products. Learn more about our company, the underlying idea, and the people behind our plastic packaging for medical devices.

These days, medical device packaging must meet extremely stringent requirements. From protection against dirt and mechanical damage to complete safety with regard to biological contamination – medical packaging must tick many different boxes. Above all, packaging for sterile medical devices demands the highest levels of precision and quality.

Discover our B2B online shop!

Enjoy the exklusive advantages and place your orders conveniently whenever it suits you - 24 hours a day, 7 days a week.

We offer versatile packaging solutions for the following industries:

Made to measure: Develop your customized packaging solution with us

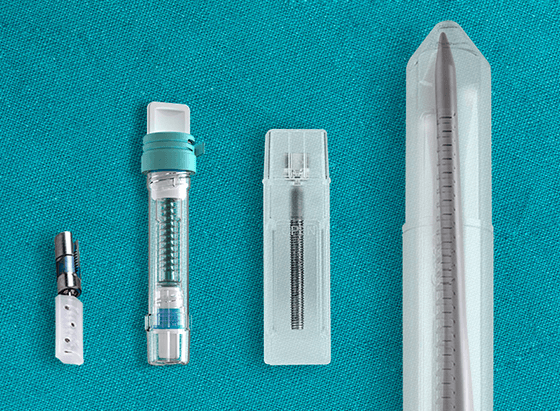

Our expertise covers both primary packaging, which is in direct contact with the medical device, and secondary packaging, which provides additional protection. In order to comply with the strictest hygiene standards, we produce many of our packaging solutions under cleanroom conditions.

Our product range includes packaging for both sterile medical devices and non-sterile medical products. Our sterile packaging guarantees that sterility is maintained until the product is used.

We not only develop and produce all our hard plastic packaging in-house – but also all the tools we need. This enables us to develop customized medical device packaging in close collaboration with our customers. So if you need customized medical packaging, don’t hesitate to reach out to us.

Trust through certification: High-quality packaging for medical devices

For the production of our packaging protective covers, tubes, cases and boxes – as both primary and secondary packaging for medical devices – we benefit from the comprehensive know-how of our parent company. Since 1953 rose plastic has been renowned for the development and production of innovative plastic packaging as well as outstanding expertise in injection molding and blow molding.

Since early 2013, under the rose plastic medical packaging brand, our company has operated as a developer, manufacturer, and supplier of packaging solutions for sterile and non-sterile products in the medical device, dental, healthcare and lab and diagnosis sectors. In March 2014, rose plastic medical packaging was certified in accordance with the international DIN EN ISO 13485 standard. Our expertise in the manufacture of medical device packaging is reflected in every one of our solutions and ensures optimum safety and quality.

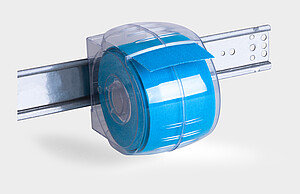

Our latest product — UniCover!

UniCover from rose plastic medical packaging GmbH is a new protective cover specifically designed to meet the stringent requirements of daily clinical practice. Discover how UniCover redefines flexibility – and optimally meets your packaging requirements.

By loading this video, you accept YouTube's privacy policy. You can find more information here.

This product combines maximum safety, versatile applications, and ease of handling, providing a packaging solution for a wide range of use cases.

New life through high-quality recycling

Plastic packaging and sustainability is no contradiction: If plastic is correctly separated after use, it is ideal for recycling. Whether it is a yogurt cup, shampoo bottle, or another type of household plastic waste. Through high-quality recycling, the old plastic can finally be brought back to life. This is the basis for the new packaging products from rose plastic. These are now available made from recycled material.

Packaging solutions for your products from the fields of cutting tools, industrial components, tool retailers & hardware stores and retail & consumer items can be found in a large selection at rose plastic AG.